Considered a dangerous occupation, underground mining is getting safer thanks to technology. For 30-plus years, NSS Canada has developed ways to make underground measurement more accurate, and the industry safer and more productive. And the best is yet to come.

Recognizing a need for the latest technology among mining clients, veteran surveyor Marty Warkentin founded NSS (Northern Survey Supply) Canada in Sudbury, Ontario in 1989. Growing the business over the decades to a team of about 20, Warkentin and wife Ann Marie took NSS Canada from its beginnings as literally a small mom-and-pop company to where it is today.

“Marty saw that there wasn’t really a unified survey supplier at the time, and every mine was handling it by themselves on their own terms,” says geologist Matthew Brown, who took over as Business Development Manager last August. “He saw that market being open for somebody to come in and offer that service externally to keep a certain level of service and expertise.”

Last December, General Manager Bruno Lalonde took over as new company president from Warkentin, chief executive officer. While the company’s general manager, Lalonde significantly contributed to NSS Canada’s growth, brand expansion and development.

“It comes with great pleasure to promote Bruno as president of NSS Canada,” said Warkentin in a media release. “Bruno’s a true leader who understands the collective and individual intelligence of our great team. We’re in the business of adding value for our clients and industry partners by integrating a wide array of measurement technologies. I’m confident under Bruno’s leadership, our company’s future is exceptionally bright.”

Underground solution

Over the years, Lalonde’s contribution to the success of NSS Canada includes the development of MOSS, short for Miner Operated Survey System. On a mine site, greater accuracy means increased productivity, efficiency, and safety, making MOSS a complete underground solution. Combined with the Hexagon Mining Portfolio, MOSS gives feedback to workers on the surface in real time, and provides a proven ROI.

Surveying is typically labour-intensive, yet MOSS enables a single worker to do the job of an entire mine survey crew. Applying technology to existing workflows, MOSS reduces work that usually requires five workers for 45 minutes to an hour each, to just one person taking 15 minutes or less. This lets supervisors re-deploy those workers and operators to other parts of the mine, improving overall efficiency and production while maintaining accuracy and precision.

Proprietary to NSS Canada, with the current iteration built in-house, the original technology was developed by product development engineer Bernie Smith long ago, when he was a Falconbridge Mine (now Glencore) employee. To explain the MOSS setup, the company created a tutorial video at www.youtube.com/watch?v=CYTtcYjgjd4&ab_channel=NSSCanada.

One of the biggest advantages of MOSS is its machine-controlled accuracy. “You’re not relying on human observation and interpretation,” says Brown.

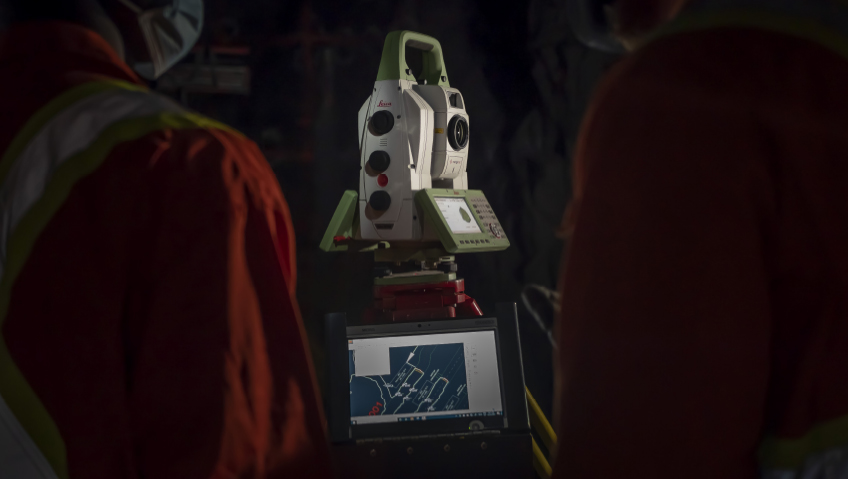

Coupled with a Total Station such as the Leica TS16 Total Station – which combines “all available measurement technologies into one superior instrument” according to NSS Canada – accuracy is improved and overbreaks are reduced by 10 to 15 percent, which leads to reduced overall costs and better savings for the mine.

“By tying MOSS to the Total Station, there is no ‘Oh, it’s close enough,’ or ‘I think it’s where it should be,’” Brown says. “The system is completely robotic in the sense that once the measurements are in the system, the Total Station does all the work. It tells the miner where to mark their holes and what angle and grade to use as they drill. Since everything is controlled there, there’s no human error involved.”

With even the most eagle-eyed workers, all humans tend to look at everything slightly differently; with MOSS and the Total Stations, the same level of accuracy is ensured every single time.

Starting in Sudbury-area mines and ballooning in the last decade, MOSS is now used by most mines in Northern Ontario, as well as across Canada. NSS Canada is also seeing its use in the American market along with trials in Mexico, and upcoming expansion in Brazil, with some units recently sold to mines in South Africa and Russia.

One system was recently sold in Fiji, because of a mine site’s need to reduce personnel, modernize operations, and because of temporary closures forced by COVID-19. Management on the mine site saw the system on an NSS Canada Instagram post.

Strategic partners

For years, NSS Canada has strategically allied itself with some of the most respected brands on the market. One of the company’s original partners was Leica, founded in Germany and known worldwide for its cameras, microscopes, and other high-end optics. Several years ago, Hexagon Mining purchased Leica, incorporating Leica’s many years of experience and innovation into its portfolio. Today, NSS Canada is an Authorized Reseller of Hexagon Mining, and a provider of sophisticated mining solutions.

“We are showing their new techniques,” says Brown. “One of the things we are working on is incorporating augmented reality and virtual reality. Mining is moving toward being more automated, and physically removing people from the working areas of the mine. So we are trying to offer alternatives to people who have to physically be there to do something to be able to do it from a safer distance, or to remove them from that process entirely.”

Through vastly improved technology, mines of the future will boost surveying accuracy, reduce manpower, and increase safety. In recent years, Brown keeps seeing the “Industry 4.0” tagline, as mining becomes much more data-driven.

“I think we’ll continue to see a trend toward automation,” he affirms. “They are trying a lot of different solutions to collect that data, but now the conversations are changing about how to use that data, and how is it applicable to get more production, safety, and efficiency? I think companies like NSS Canada that have expertise find that it works in their favour, because we can come in and show them how best to use that data based on what we are seeing on our sites, or we can be the guides to get that technology in place and get those workflows developed.”

Taking drones below

Throughout history, technology has always “leaked” – what is used for one purpose will eventually find its way into other applications. One of the best examples is drones.

Adopted by hobbyists to get an aerial view of neighbourhoods and nature, drones are today used on above-ground mine sites for surveying. Now, incorporating the fruits of its own experience into existing drone technology developed through other innovations, NSS Canada is creating advanced tools for underground mining operations.

“A lot of that technology is getting so cross-pollinated between industries that as long as you can prove it works for one area, they are able to put it into mining, or at least give it a fair go,” says Brown. “There seems to be a lot of money for technology lately, so companies are willing to try anything and everything to make their mines safer.”

Most impressive of all is, if there is good underground infrastructure, everything can be done seamlessly. “The drone does the mission,” Brown says. “It goes in, does its scan, turns around by itself, and that information gets pushed to the operator as the drone gets back in range.”

Night and day

Yesterday’s drone technology compared to today’s is night and day, says Brown. Operators do not need a pilot’s license to operate the drone because it is autonomous and so sophisticated that it won’t bump or crash into walls; very little human training is involved, other than how to use the software and a tablet.

“The actual drone itself and the technical piloting is completely removed. Mines see it as a benefit, because you only have to rely on one operator. Before, if you only had one drone pilot and they took their holidays or were off rotation, you couldn’t do anything. So now it seems autonomous is the way to go, and a lot of the older technologies are moving toward it.”

Able to map up to six million points per second and equipped with cameras and Lidar (Light Detection and Ranging using pulsed lasers to measure ranges), outstanding 3D resolutions are created, better than any that can be done solely by camera.

Along with unparalleled accuracy, another benefit of the technology is speed. Open spaces in mines known as a stope measuring 160 to 200 feet (48 to 61 meters) can be analyzed in two minutes, a process that used to take anywhere from 25 minutes to an hour, depending on the type of resolution needed.

Looking out for local

Even with rapid technological advancements, the company has never lost the human touch. As a proud Sudbury-based business, NSS Canada strives to source all the services, supplies and tools it needs locally. Most of the people the company hires are also from nearby, or based in Northern Ontario, to keep the local economy strong.

“We know everybody is going through a tough time, so we pride ourselves on being the kind of team that if somebody comes to us and says, ‘we have this problem,’ and we know we can’t solve it but we know somebody else who can locally – even if they are our competition – we direct that person to the local company,” says Brown. “It makes sense that they go with somebody [local], even if it’s not us, because it is still benefiting the town and Northern Ontario.”

It is this kind of community- and client-focused approach that has led NSS Canada to ongoing success.